Back Orders

What do Back Orders tell you? What they potentially tell me are things like:

- These are the items you’re in trouble on RIGHT NOW.

- These are the items where current demand exceeded quantity on hand and/or exceeded routine anticipated demand (a spike in demand).

- These items might have an inventory error.

- These items might be miss-located.

- These are the items that were ordered late or the supplier shipped late.

- These items might have a BOM (bill of material) error or a recent ECN/ECO (engineering change) that was not implemented or misinterpreted.

- There might be a Quality Control issue.

- The supplier might have issues or is not reliable.

- These are the items that were improperly planned.

- Some body is not paying attention.

I would urge everyone to examine numbers 1 thru 6 before looking at #7 and furthermore.

No matter what you might think or believe, Back Orders tell you there is something wrong.

Although, with that said, if your enterprise does not have the occasional back order then you might very well have another problem. We should all take heed here. These two items are not mutually exclusive, but rather different sides of the same coin.

So what is the correct answer? Well, they both are, in the sense that you want just enough inventory on hand to cover demand and the demand during lead time but no more. It’s acceptable, and probably ideal, to have a backorder if the material is arriving before start of business tomorrow. That is assuming, of course, when the demand will hit.

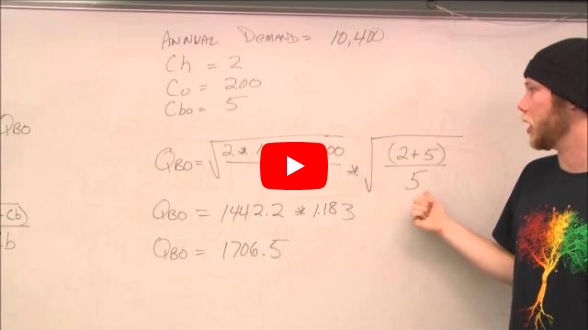

Many planners and enterprises forget the basics of order quantities. The calculation should be something like:

Quantity on Hand + Quantity on Order – Current Existing Back Orders – Upcoming Demand during the Lead Times = Quantity to be Ordered this cycle.

Or

100 +75 – 50 – 90 = 35 at a minimum (taking lead time into consideration).

Not all is lost and there are ways to protect yourself and your company and they are all perfectly legitimate. Let’s assume that you and your company have an approved supplier list and furthermore let’s assume you have a professional and good working relationship with all of them. At this point it’s perfect to assume that based on an ongoing relationship you could request that your supplier maintain a safety stock for you of some reasonable quantity that you will, of course, guarantee to accept.

Alternatively your purchasing department could contractually agree for the supplier to maintain a 30 day supply on hand until termination of the contract.

Yet again, the supplier might reduce your lead times so you can order smaller quantities more often.

Or even more dramatically, the supplier might agree to some “vendor consigned inventory.” There are many variations to this but in its simplest form the supplier would place some quantity of HIS inventory in YOUR WAREHOUSE and bill you as you use it. This, of course, requires mature inventory, production, and accounting systems along with trust and detailed specific contracts with action items and terms of remediation.

Your path to business success.